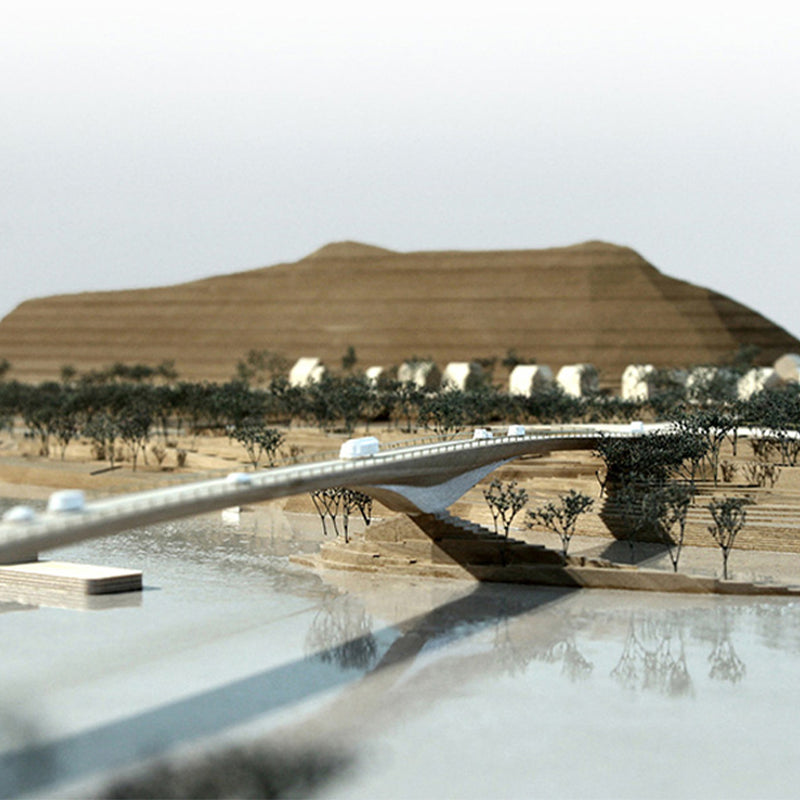

Golda-Meir-Steg

Project Details +

Project Details

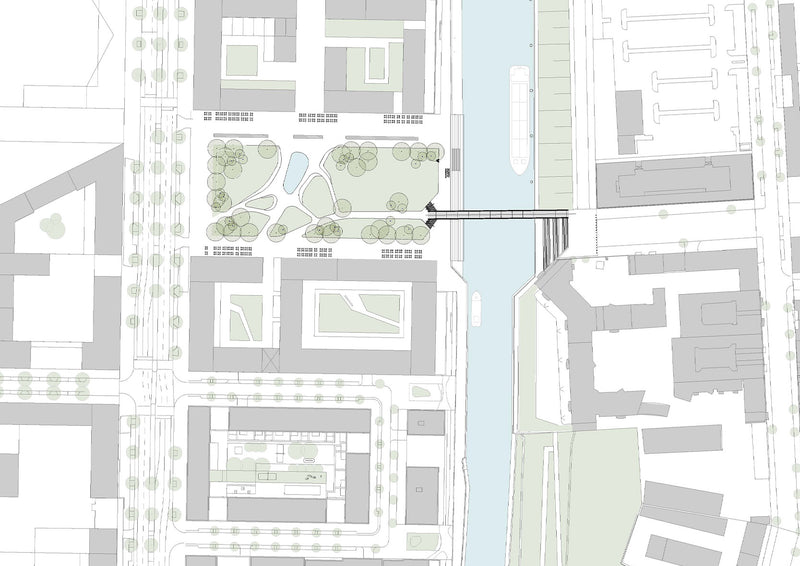

LOCATION: Europacity, Berlin

CLIENT: Berliner Senat - Abteilung Tiefbau

DATE: 2014-2021

STATUS: Completed

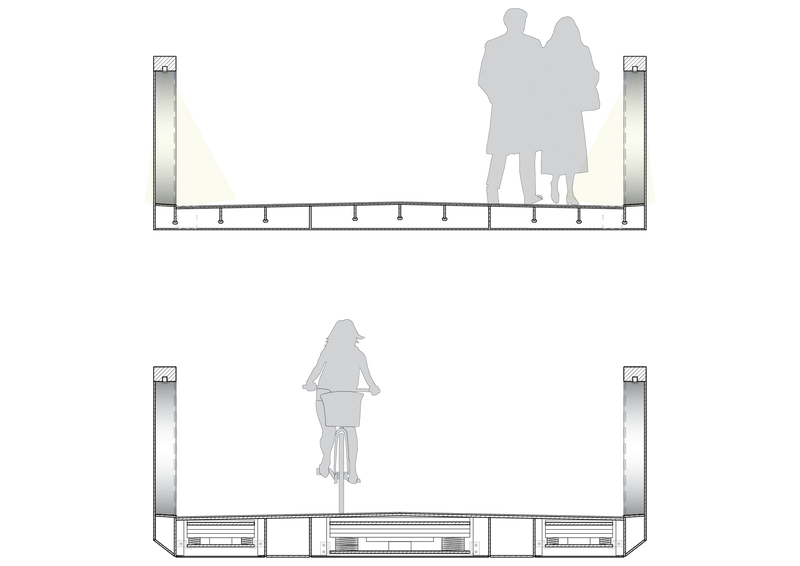

SIZE: Length: 77m, Width: 4m, Clear span: 60m, Clear height 4,5m

Credits +

Credits

ACME: Sarah Blahut, Nicholas Channon, Vera Landshuter, Friedrich Ludewig, Martin Menacher, Sarah Norman, Heidrun Schuhmann

CONSULTANTS

Competition:

Structural engineer - AKT II

Quantity surveyor - Höhler+Partner

Lighting design - SEAM Design

Execution:

Executive Architect/ Structural engineer - Schüssler Plan

Construction supervision - BögerJäckle

Lighting - LichtKunstLicht AG